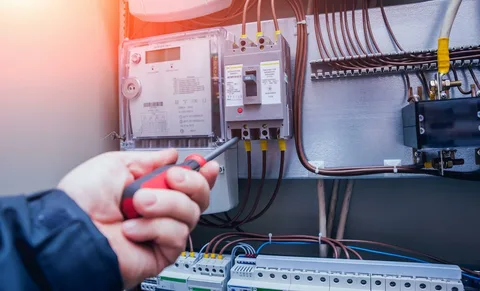

How Does Corrosion Occur in Electrical Panels, and Why Should Electrical Panels be Upgraded – 2024?

The reliability of electrical panels is critical to the complex system that powers the modern world. But against the needs of Durability and usefulness, corrosion becomes a strong enemy.

To protect against corrosion’s harmful effects, one must understand how it enters the electric panel.

Numerous reasons, such as moisture entry or chemical exposure, can cause corrosion to start, which puts personnel safety and equipment maintenance at risk. It is important to upgrade electrical panels in this day full of technological improvement.

We can reduce the risks related to corrosion and guarantee the reliability and strength of our electrical infrastructure in 2024 and beyond by implementing modern technologies and regular maintenance techniques.

Understanding Corrosion in Electrical Panels

Corrosion in electrical panels is a quiet enemy that works its way through our electrical systems and makes them less useful.

At its most basic level, corrosion is the slow breakdown of metal parts caused by chemical reactions with their surroundings

Its slow growth is helped by things like moisture getting in, levels of moisture, and chemical contaminants. Corrosion can make electrical links less conductive if it is not stopped. This can cause voltage changes, overheating, and finally system failure.

To take precautions against corrosion and keep the purity of electrical panels, it is important to understand how it happens. We can protect our electrical infrastructure from this constant threat by doing regular repairs, careful inspections, and using materials that don’t rust.

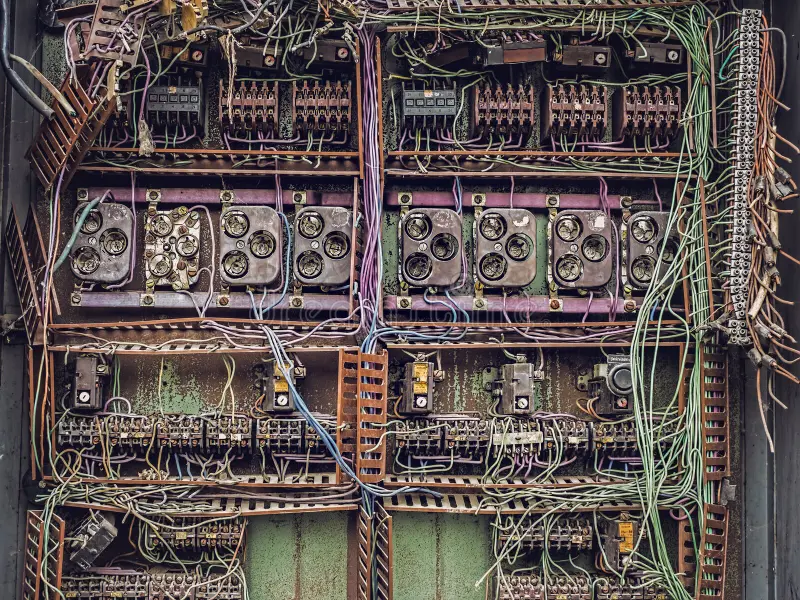

Effects of Corrosion on Electrical Panels

Corrosion can do a lot of damage to electrical panels, which can be very bad. It can make electrical links less conductive, which can lead to overheating and even fires

Corrosion also weakens the structure of panels, which makes it more likely that equipment will break down and need expensive fixes.

To lessen the bad effects of corrosion, it’s important to do regular inspections and upkeep.

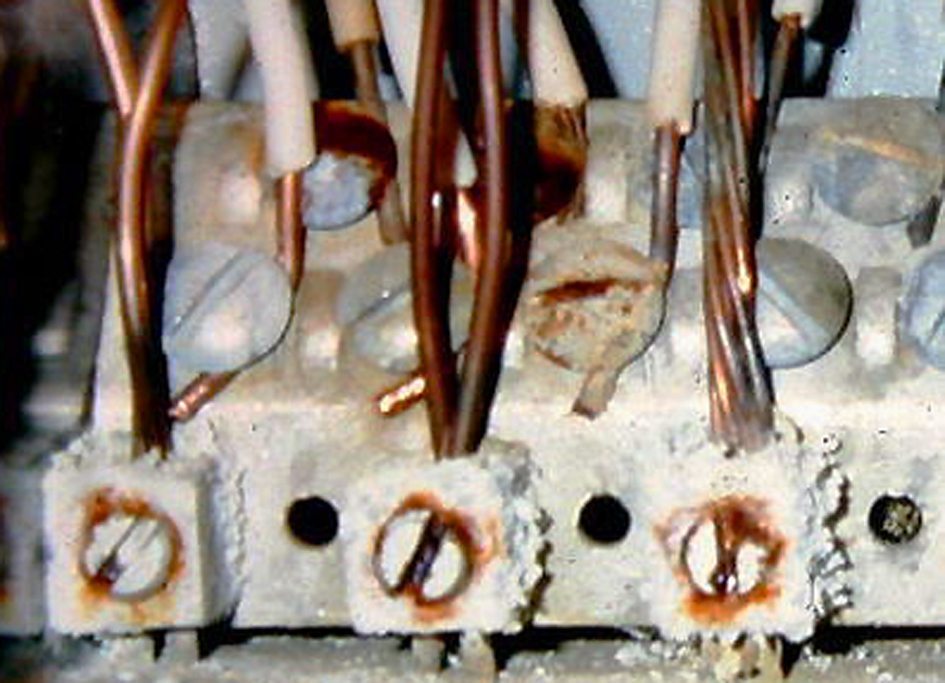

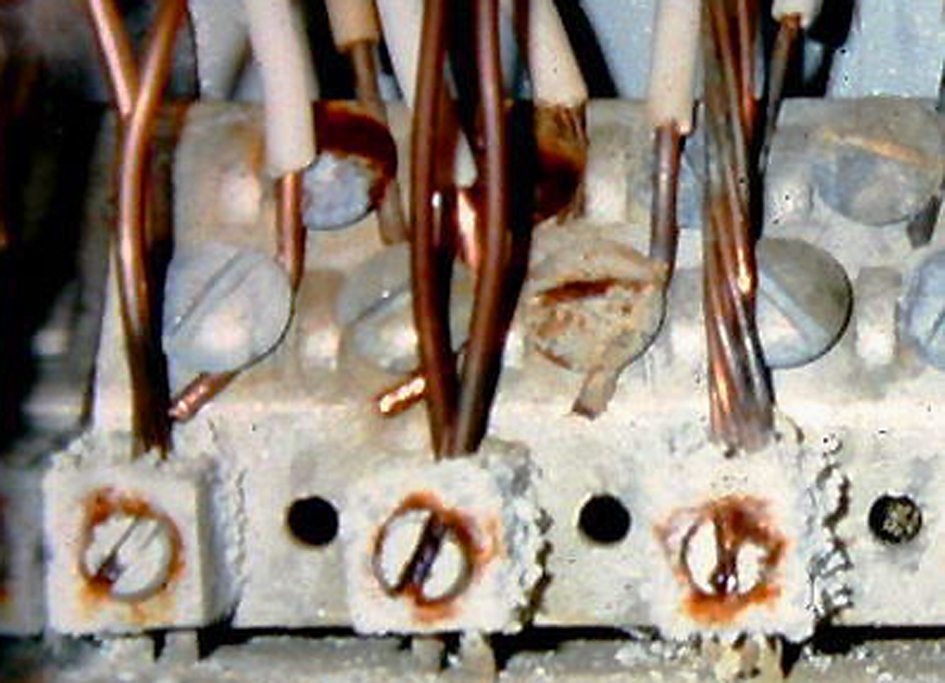

- Compromised Conductivity

Corrosion makes it harder for electricity to flow through electrical panels, which raises resistance and lowers conductivity.

This can cause voltage drops, parts to get too hot, and possible electrical hazards, which can be dangerous and make tools less effective.

- Overheating and Fire Hazards

Corrosion builds up on electrical parts and links, creating resistance that causes heat to build up.

Over time, this can lead to overheating in some areas, the melting of insulation, and the possible burning of dangerous substances nearby. This can make the panel and the areas around it more likely to catch fire.

- Structural Integrity Compromise

Corrosion damages the structure of electrical panels by eating away at metal covers, mounting tools, and support structures.

This wear and tear makes panels more likely to get damaged physically, be stressed by the environment, or break mechanically, which threatens their reliability and longevity.

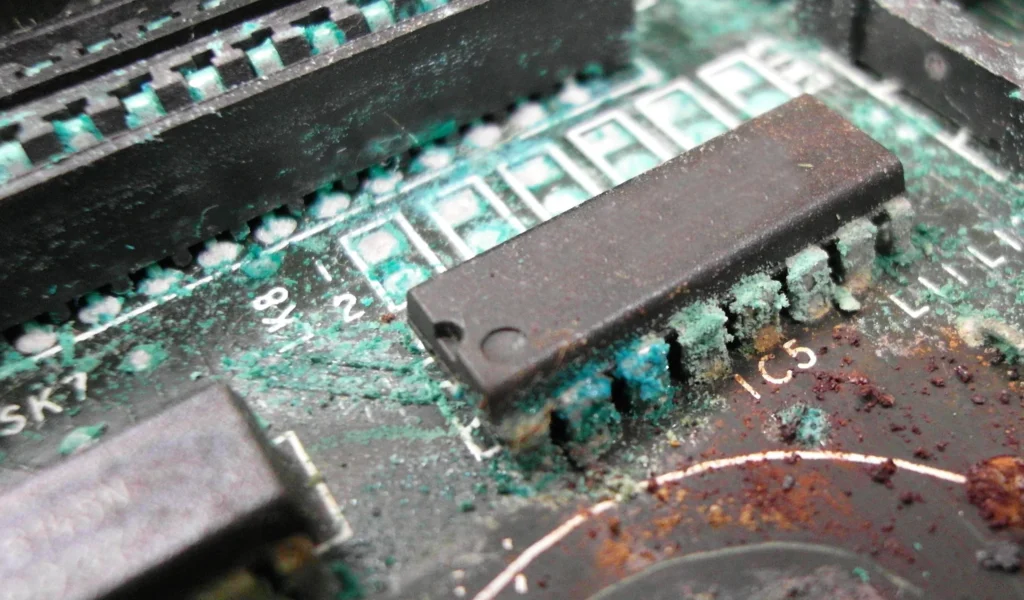

- Equipment Failure and Repair Costs

Breakdown caused by corrosion can cause technology to break down early, requiring expensive repairs or replacements

Electrical parts and connections that break down affect how well and how well panels work, which can cause problems and cost companies and organizations a lot of money in maintenance costs.

Identifying Corrosion in Electrical Panels

To keep systems from breaking down and keep people safe, it’s important to find rust in electrical panels. Corrosion can be seen by looking at something closely and looking for rust, staining, or cracks.

Keeping an eye on changes in temperature and doing regular maintenance can also help find rust early and fix it quickly, which lowers the risk of damage to electrical systems.

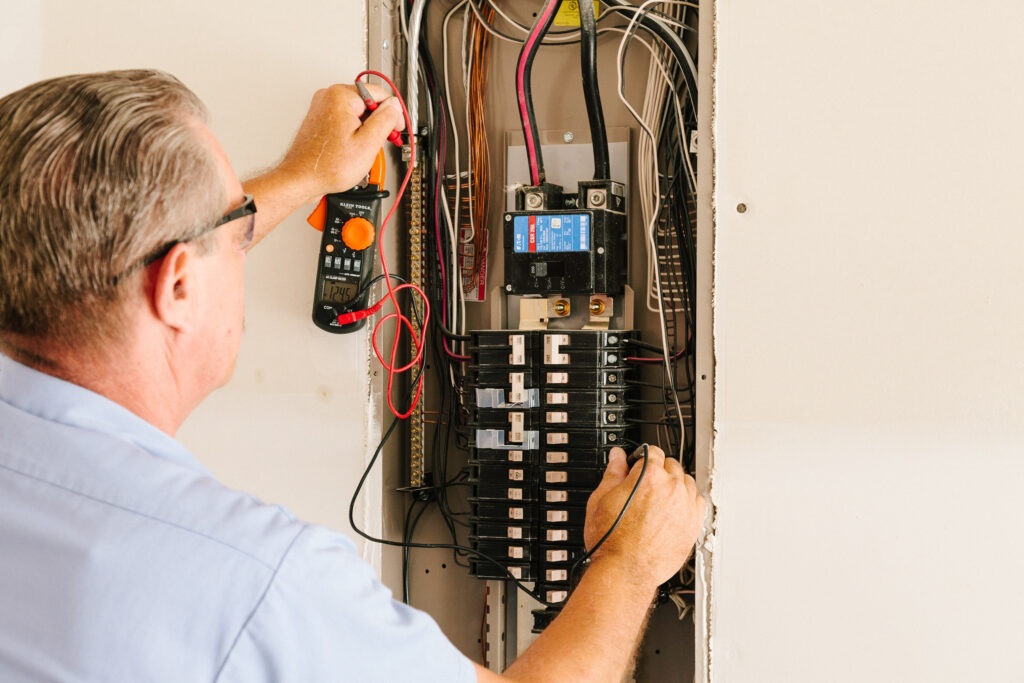

- Visual Inspection Techniques

Do full eye checks of the electrical panels, looking for rust, discoloration, or damage on the metal parts. Connections and connectors are likely to rust, so pay extra attention to those areas.

- Temperature Monitoring

Keep an eye on changes in the temperature inside electrical panels, as too much heat can speed up the rusting process

Using infrared thermography or temperature monitors can help you find strange temperature patterns that could mean problems with corrosion.

- Regular Maintenance Practices

Set up a regular maintenance plan for electrical panels that includes cleaning, tightening connections, and coatings that won’t rust. Corrosion can be found and fixed before it does a lot of damage by doing regular maintenance and inspections.

- Utilization of Diagnostic Tools

To assess the extent of rust in electrical panels, utilize diagnostic tools such as corrosion meters or conductivity testers

These instruments provide numerical data, enabling precise monitoring of corrosion levels over time. Such measurements enhance accuracy in detecting and tracking corrosion buildup effectively.

Causes of Corrosion in Electrical Panels

Many factors, such as exposure to moisture, chemicals, temperature fluctuations, and material degradation, can cause corrosion in electrical panels.

To take precautions and keep electrical systems working properly, you need to know what these reasons are:

- Moisture Ingress

Electrical panels rust when they are exposed to water, either through wetness or water leaks. Oxidation processes on metal surfaces are sped up by moisture, which causes rust and corrosion.

- Chemical Exposure

Pollutants chemically, like salts, acids, or industrial waste, can eat away at metal parts in electrical panels. When these toxins come in contact with metal, they break down and rust over time.

- Temperature Fluctuations

Changes in temperature can make rust worse in electrical panels. When metal parts change shape due to temperature changes, microcracks can form that let water and other pollutants in, which speeds up rusting.

- Material Degradation

The materials used in electrical panels may deteriorate over time due to age, wear, or poor work. The barriers that keep corrosion out get weaker over time, which makes the panels more open to damage from the surroundings.

The Effects of Ignoring Corrosion

If you don’t take care of corrosion in electrical panels, it can cause problems like lower performance, higher safety risks, equipment failures, and expensive fixes.

If you don’t pay attention to corrosion, it can make electrical systems less reliable and safer, which can put people and property at risk.

- Performance Degradation

Neglecting corrosion in electrical panels results in power changes, overheating, and decreased performance, reducing the system’s utility and efficiency.

- Safety Hazards

Corroded electrical panels are very dangerous because they make electrical shocks, fires, and crashes more likely, which puts people and property at risk.

- Equipment Failures

If you don’t fix corrosion, it will eventually break down your equipment, which will stop activities and cost a lot to fix or replace.

- Financial Implications

Neglecting corrosion can lead to financial problems like repair costs, lost time at work, and possible legal problems that can hurt the organization’s bottom line and image.

Benefits of Upgrading Electrical Panels

There are many benefits for residential as well as commercial properties that come with improving their electricity panels.

Some of the main benefits are better safety features, more power to handle modern electrical loads, lower energy use, and compliance with current electrical codes.

Also, updated panels lower the risk of electrical fires, make the system more reliable, and give property owners peace of mind.

- Better safety features

Advanced safety features like circuit breakers and surge protection are built into new electrical panels. These features lower the risk of electrical dangers and protect people and property.

- Increased Capacity

Newer panels have higher capacity ratings, which means they can handle the growing need for energy in homes and businesses today. This keeps the electricity system from overloading and makes it more reliable.

- Improved Energy Efficiency

Modern Circuit breaker boxes are made to make the best use of energy and waste as little as possible. This means that homeowners’ power bills are lower. Getting better panels can help you save a lot of energy over time.

Conclusion

If you don’t take care of corrosion in the Fuse box, it can put your safety, the reliability of your tools, and your finances at great risk. Upgrading panels improves safety, makes them more reliable, and makes them meet current standards. By making panel changes a top priority, businesses can lower their risks, boost their efficiency, and make sure their electrical infrastructure will last for years to come.